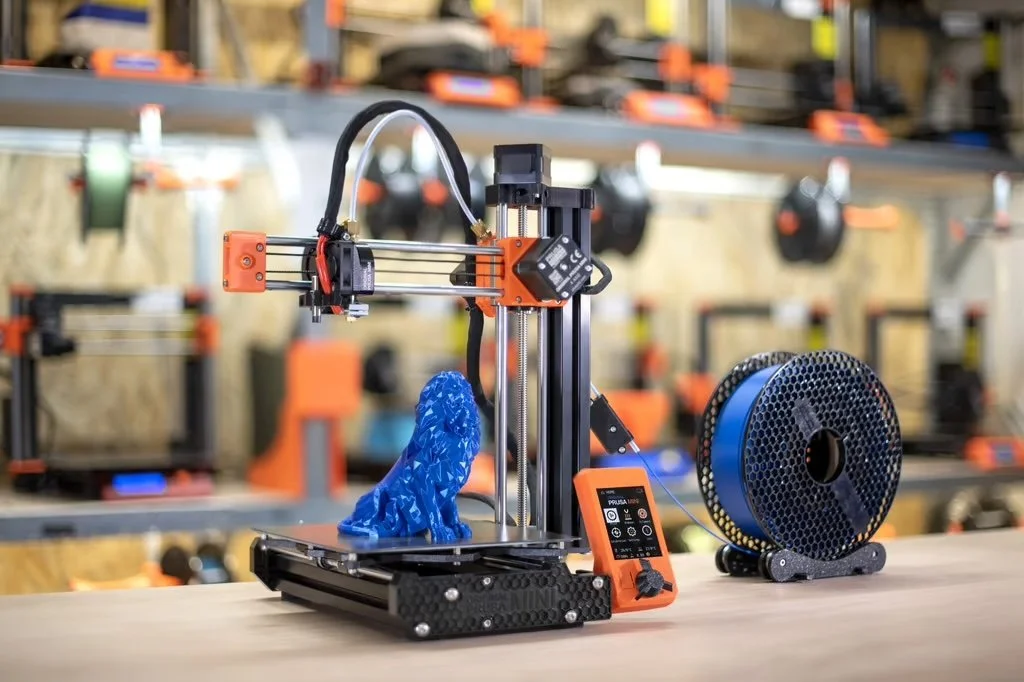

So, I get a 3D printer…

and I wonder, “what should I make with a 3D printer?

another 3D printer, of course

I present…the “Super Mini”

(click me)

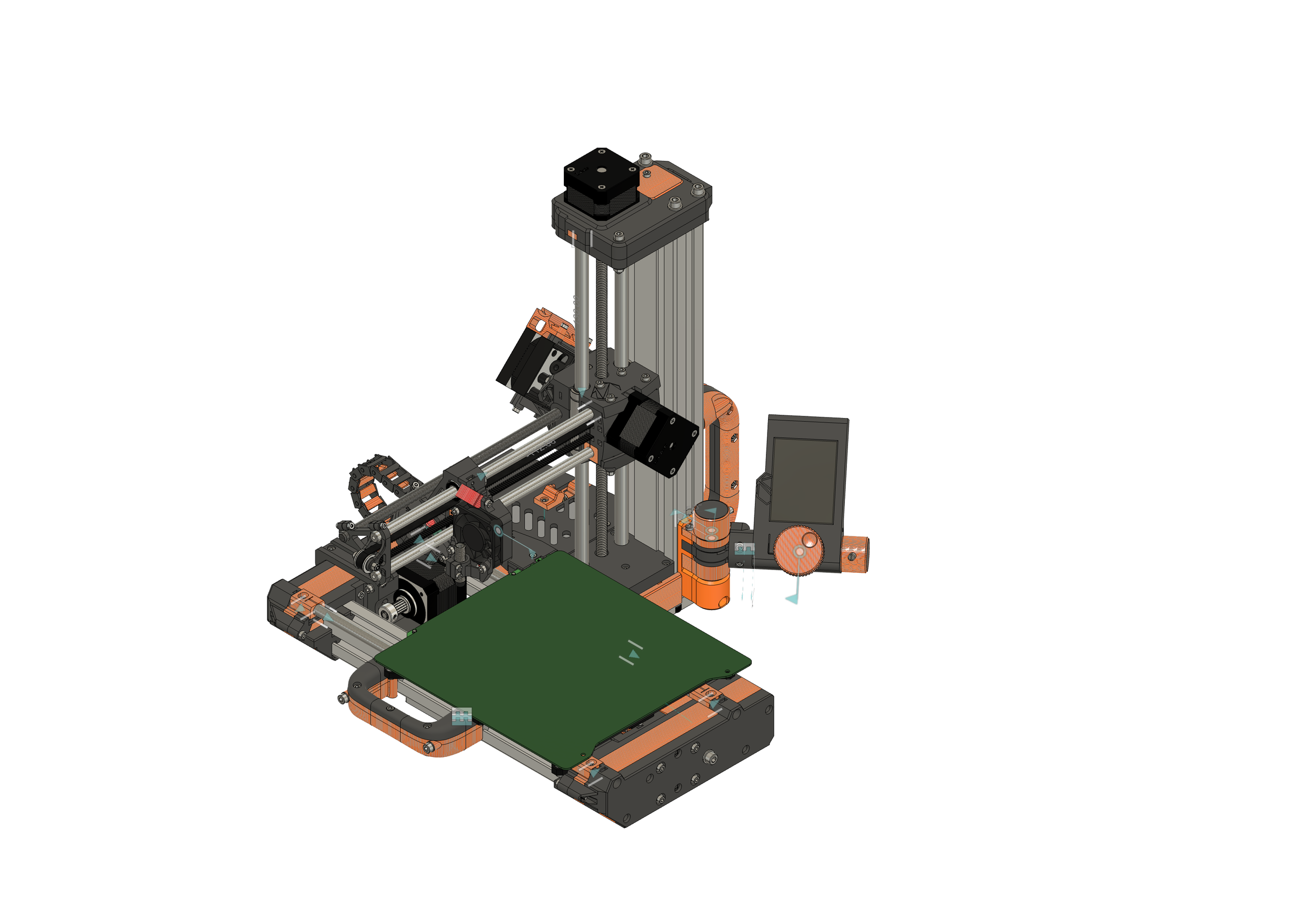

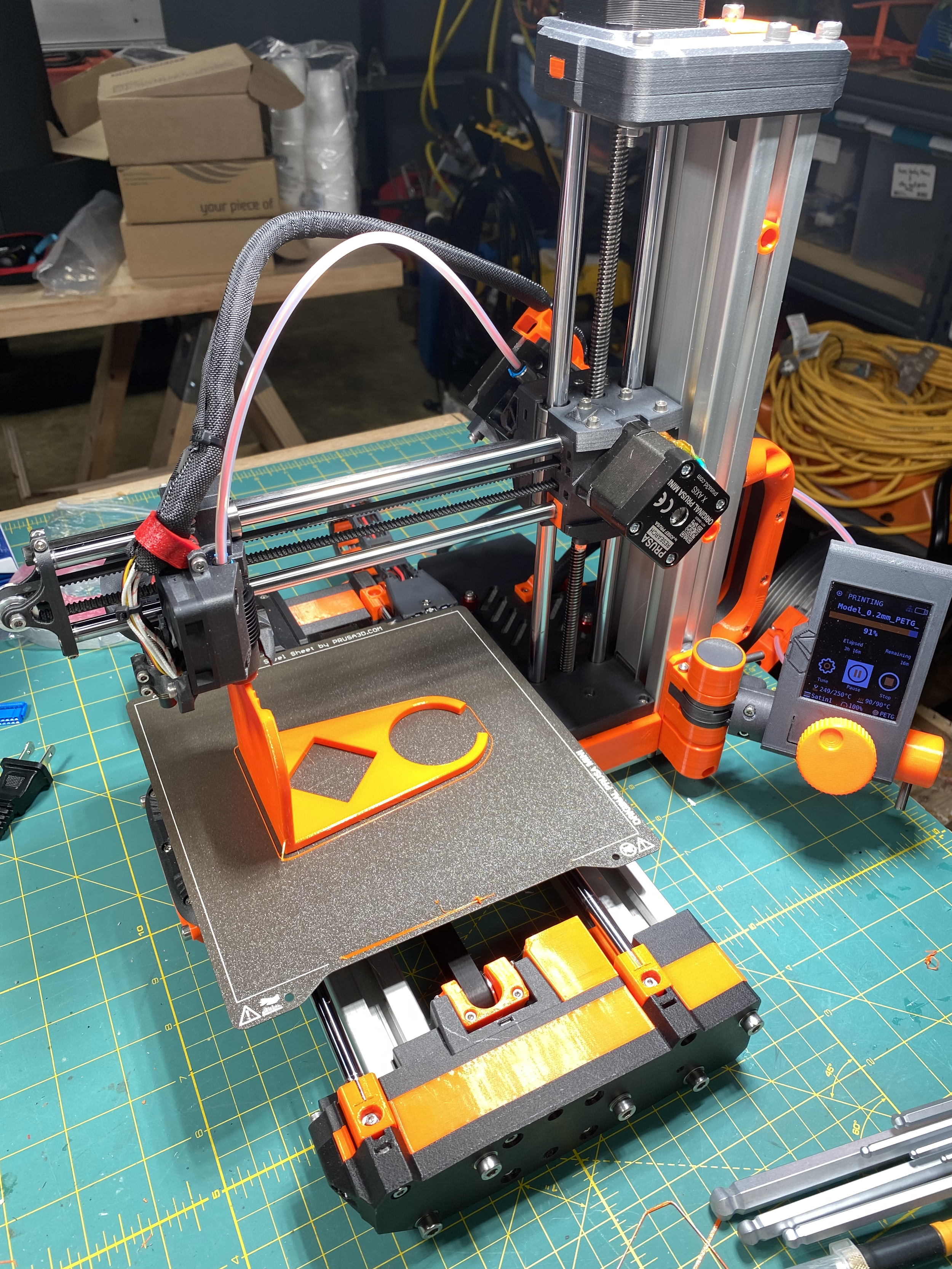

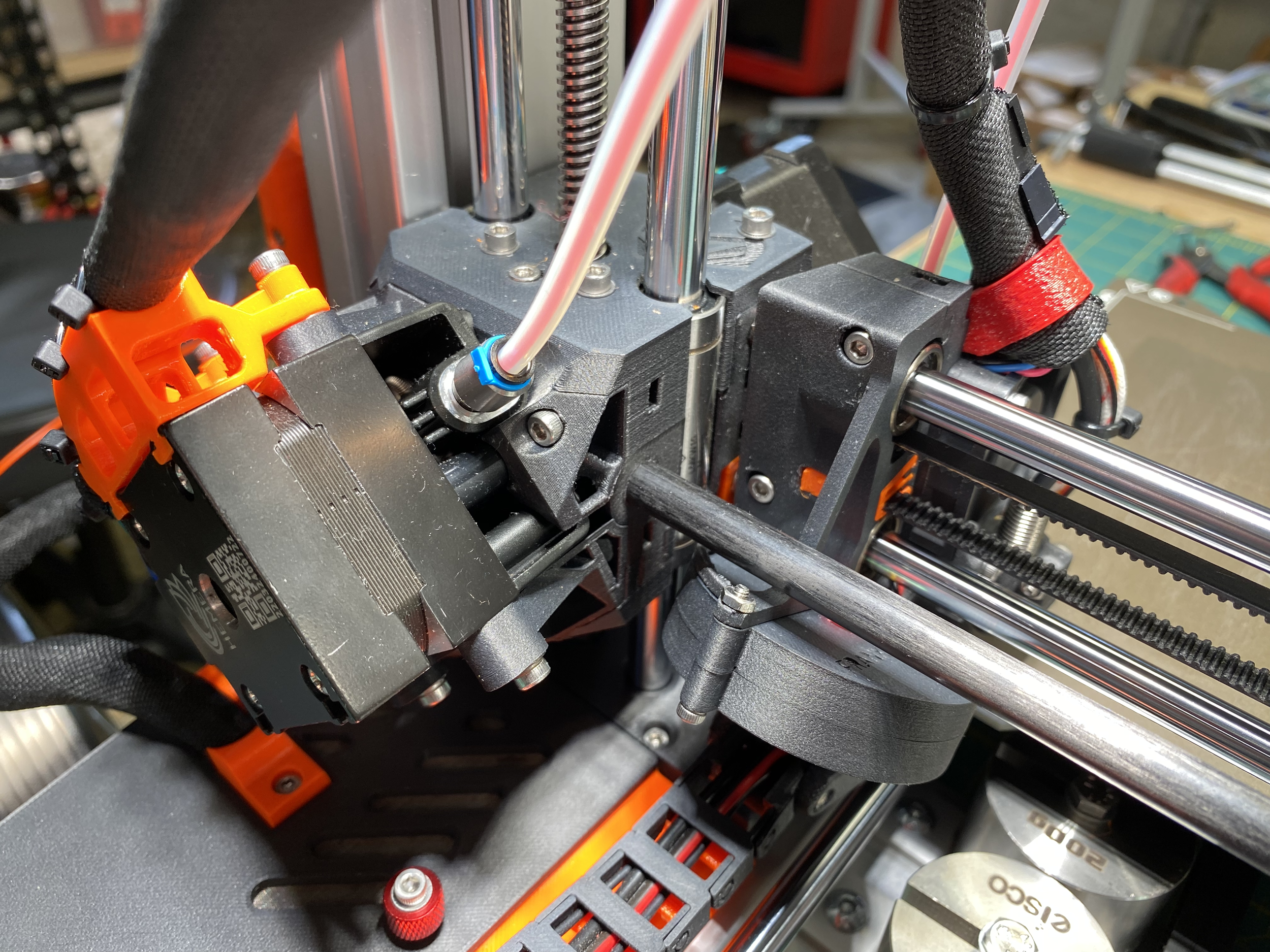

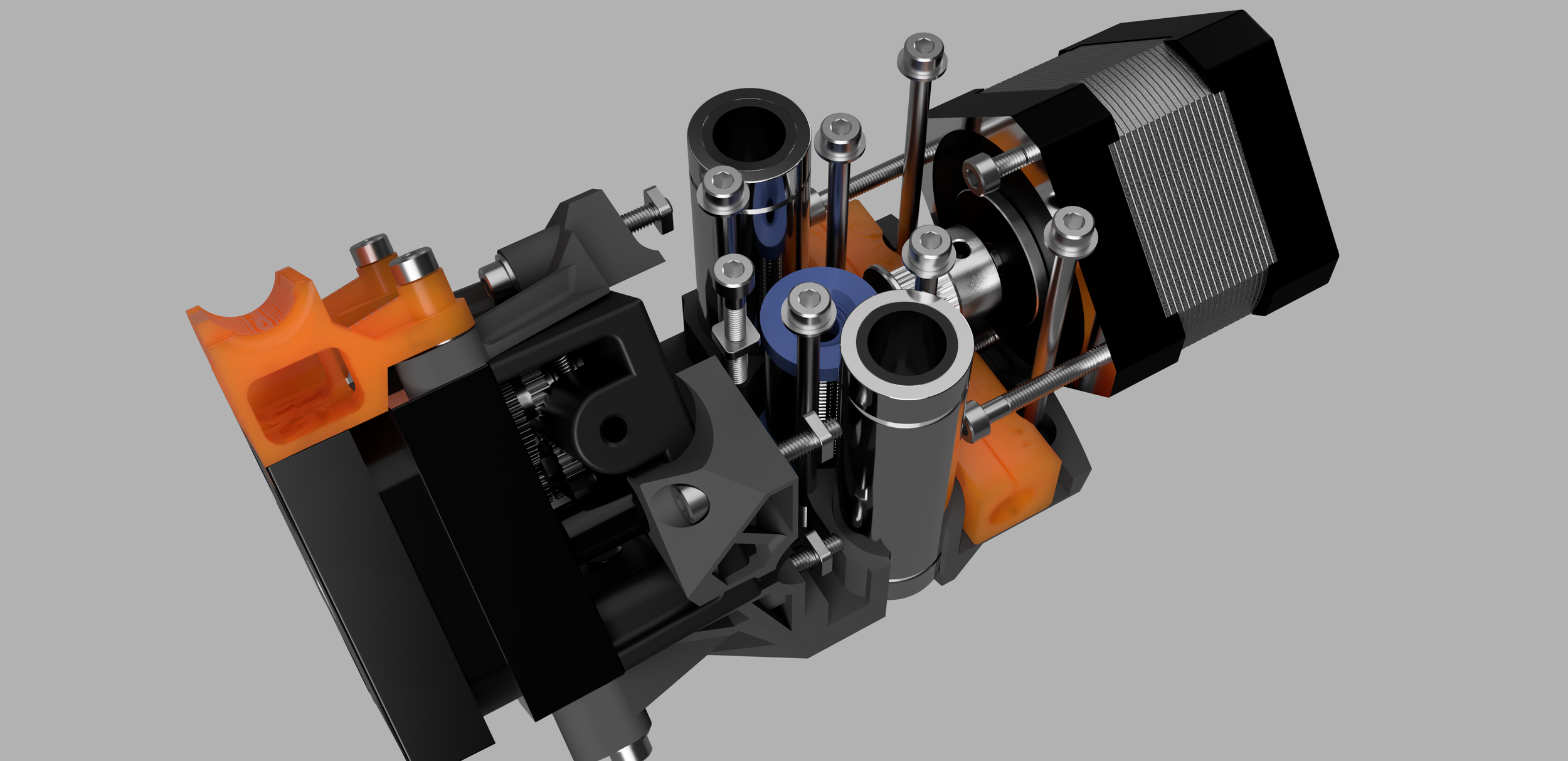

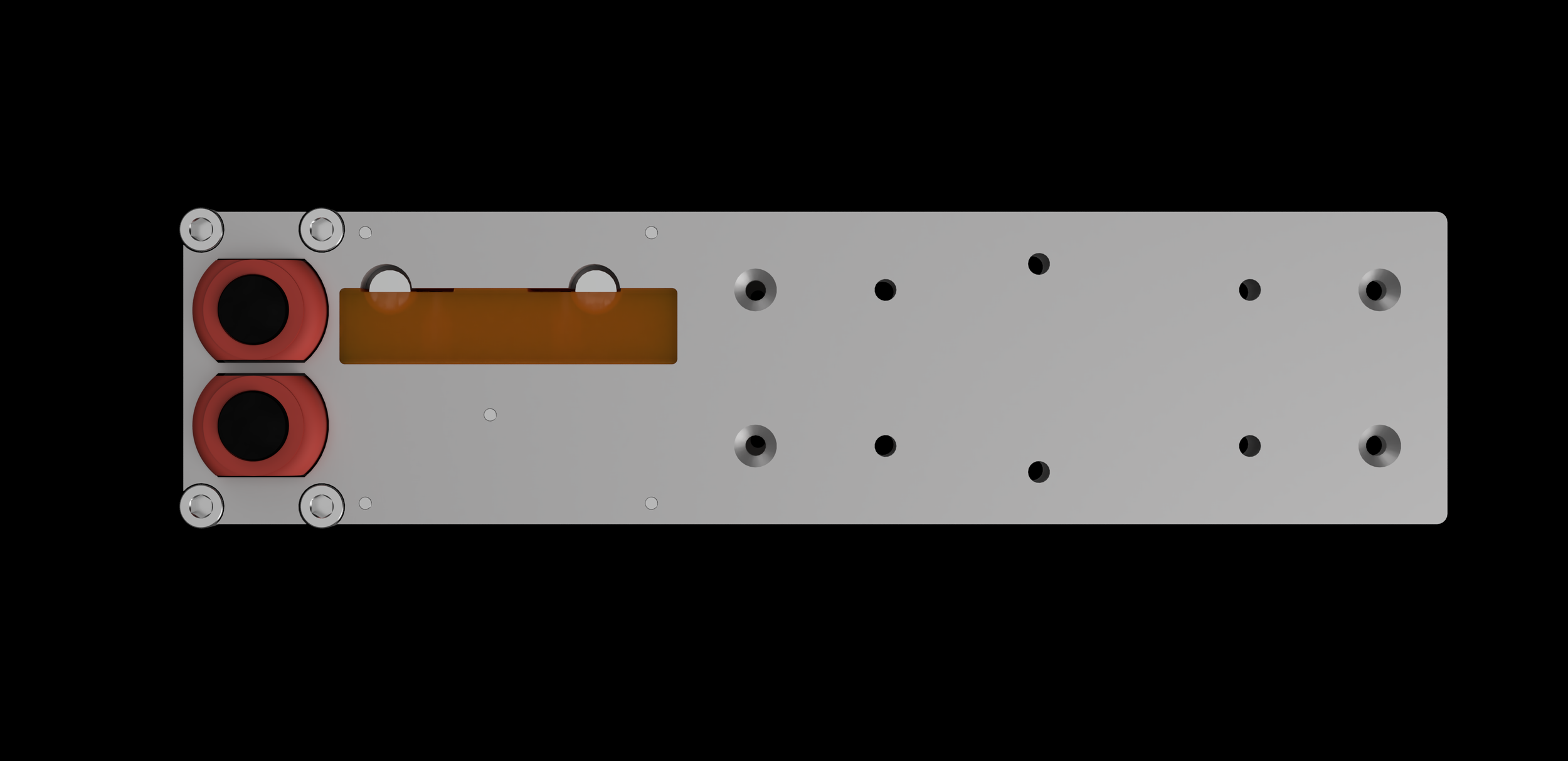

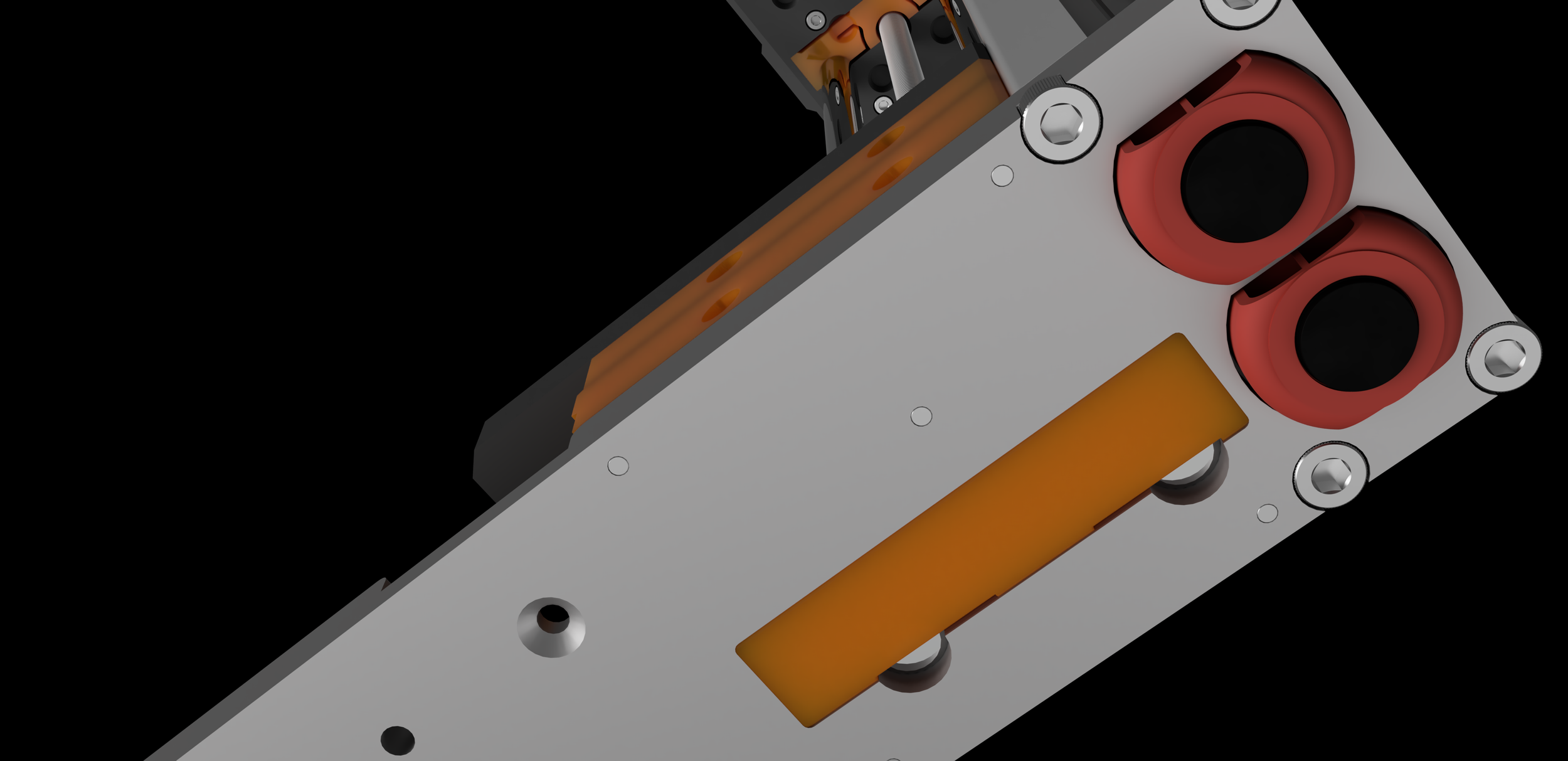

The Super-Mini™ is a completely redesigned Prusa Mini. Every part of the mechanical design, other than the actuators, was reconsidered and, in my opinion, upgraded. The focus was on stability. The base weights 2kg due to tungsten inserts in the plastic ends of the y-axis and 500g of steel lab weights under the z-axis. This is designed to reduce vibration when the printer is actuating at full speed.

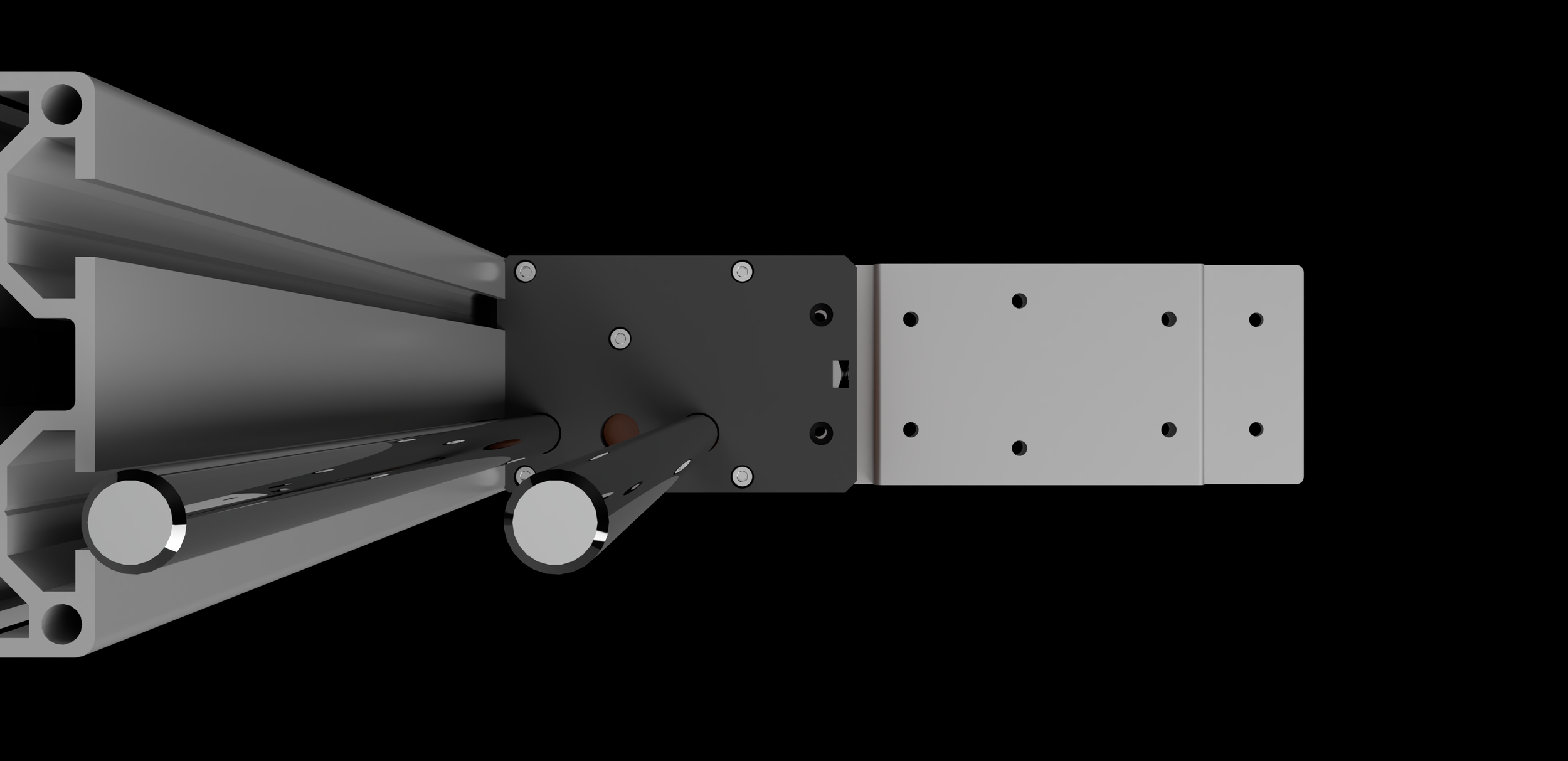

The z-axis is made from 60x30 channel bolted to a custom-machined aluminmum base that integrates with the 30x30 y-axis channels (machine work by xometry).

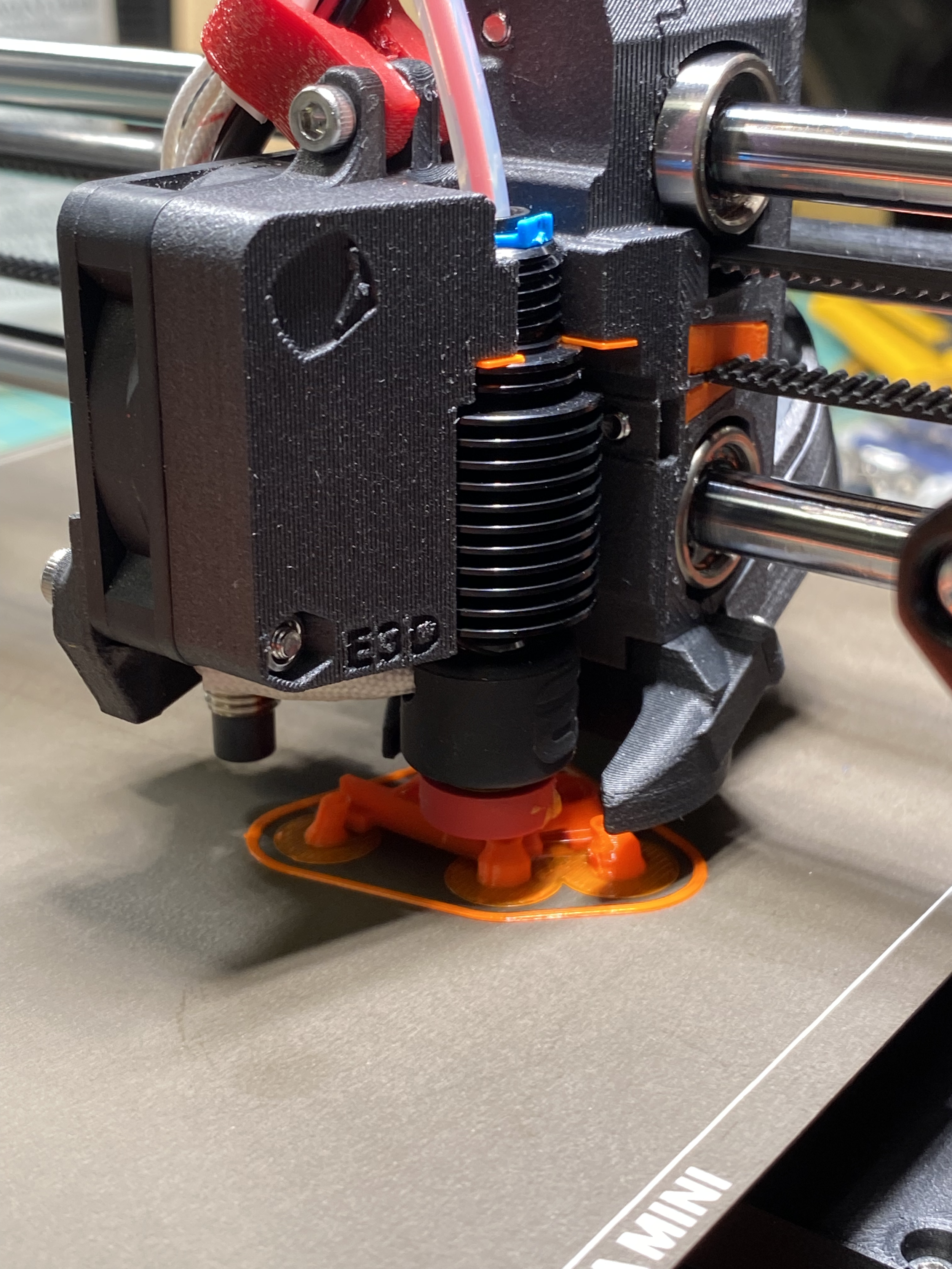

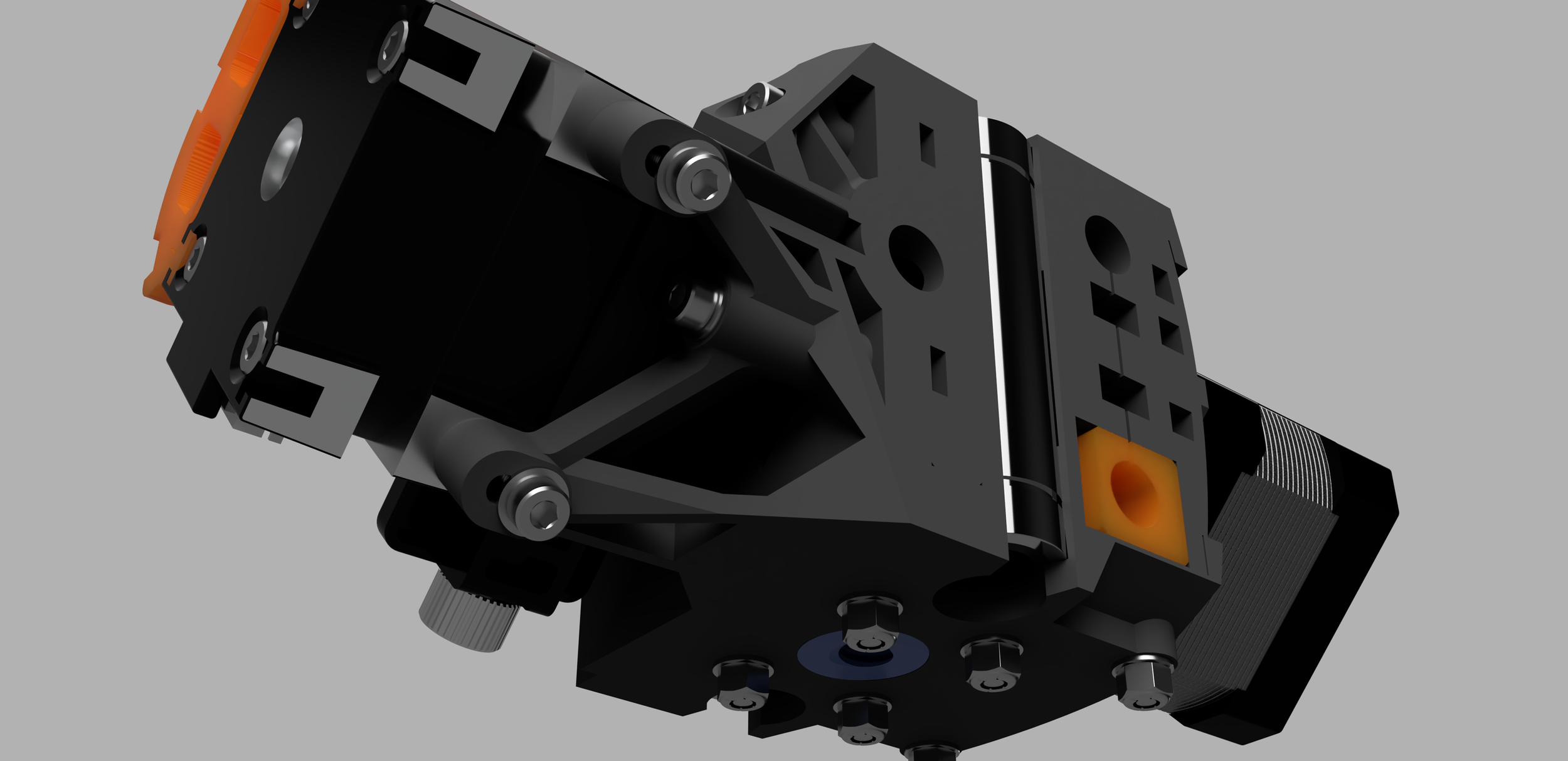

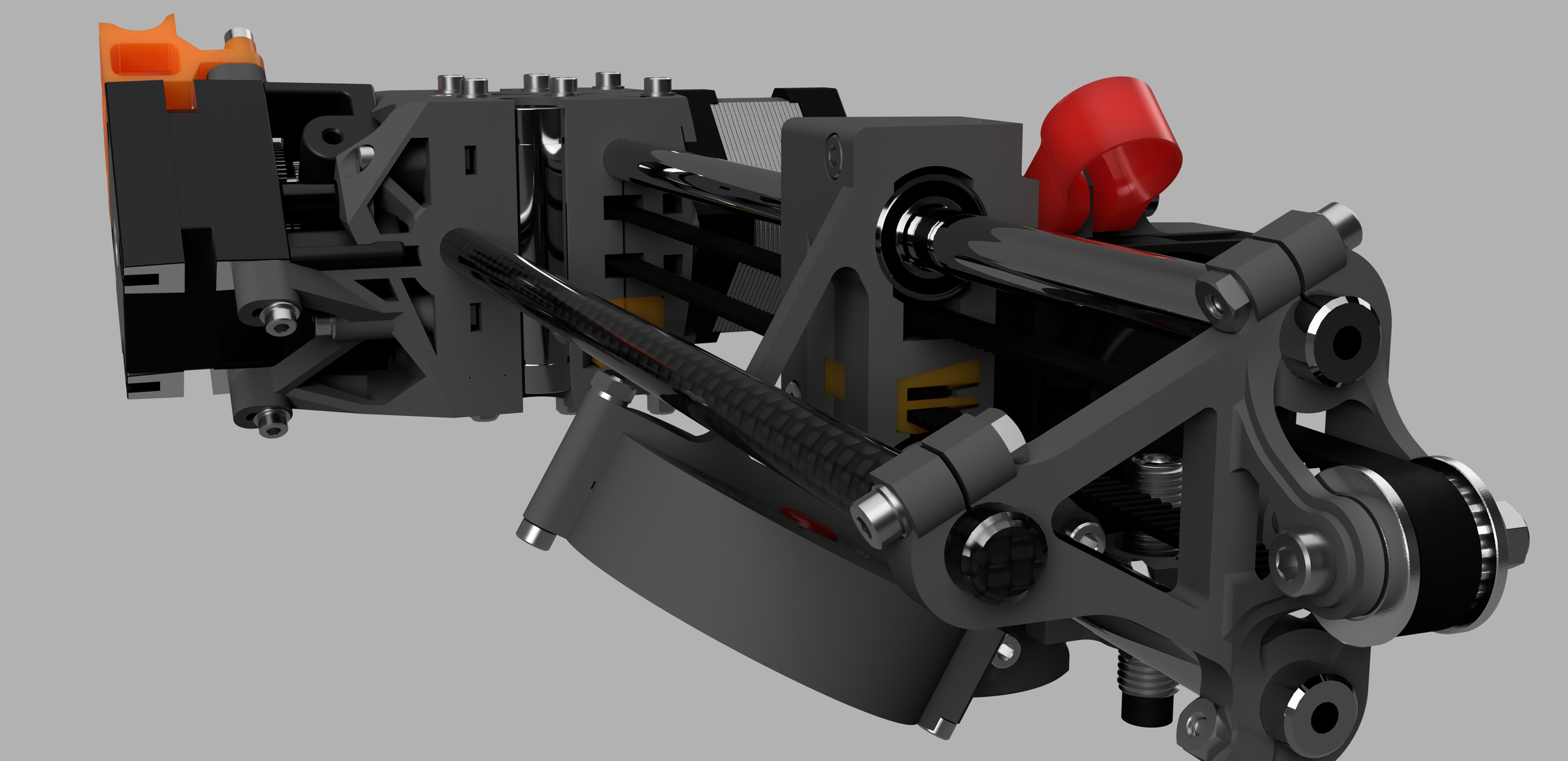

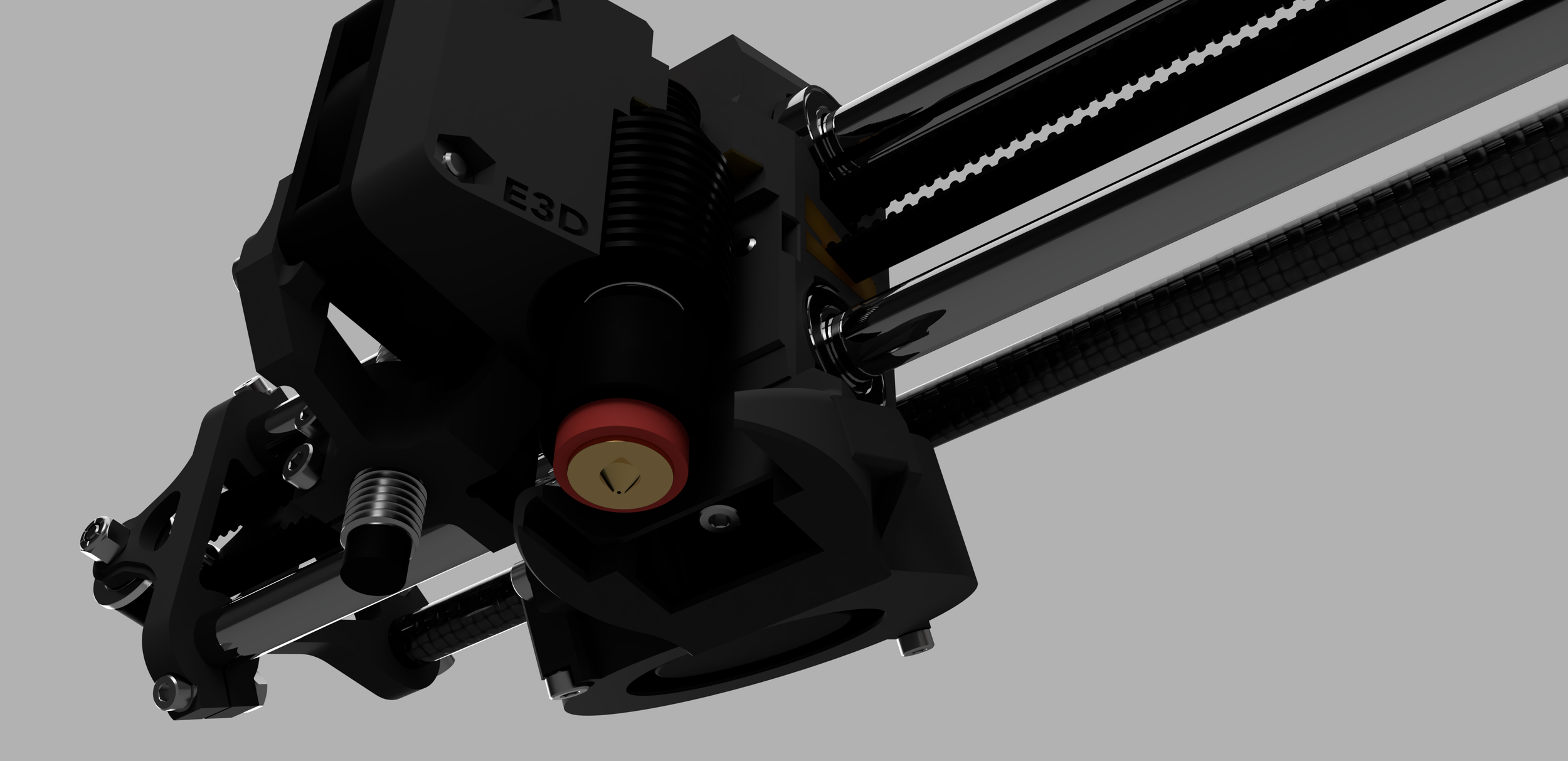

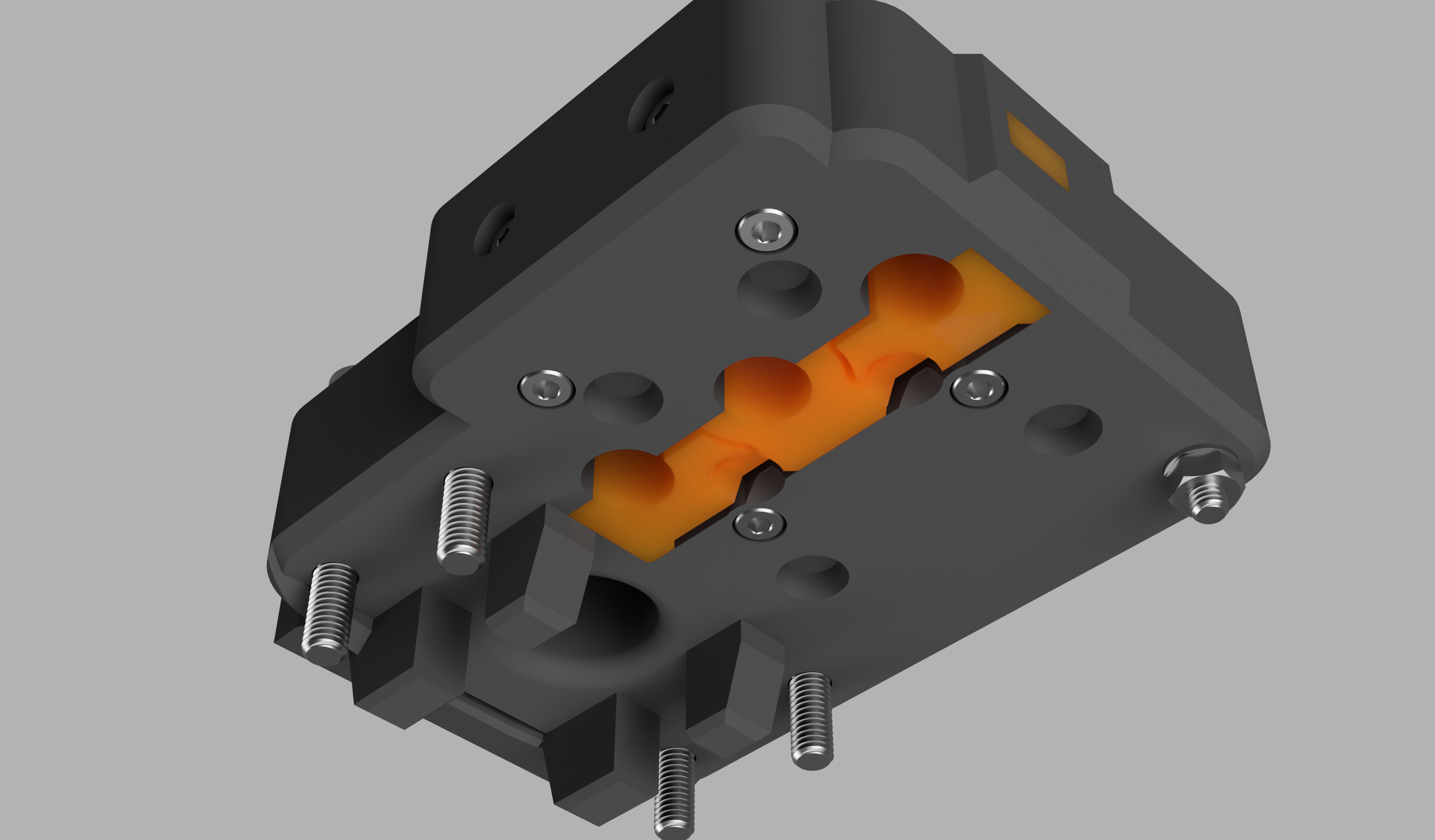

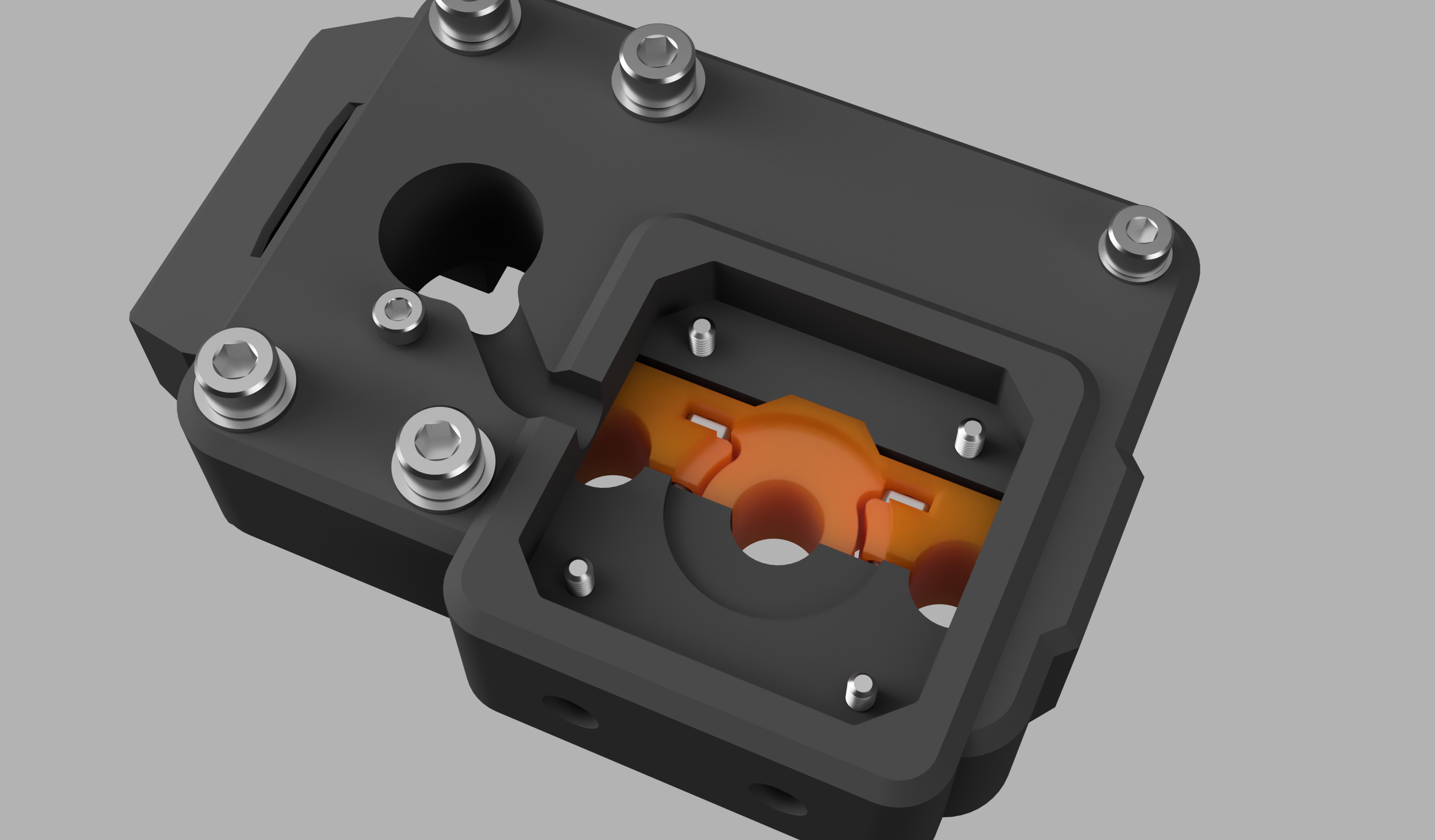

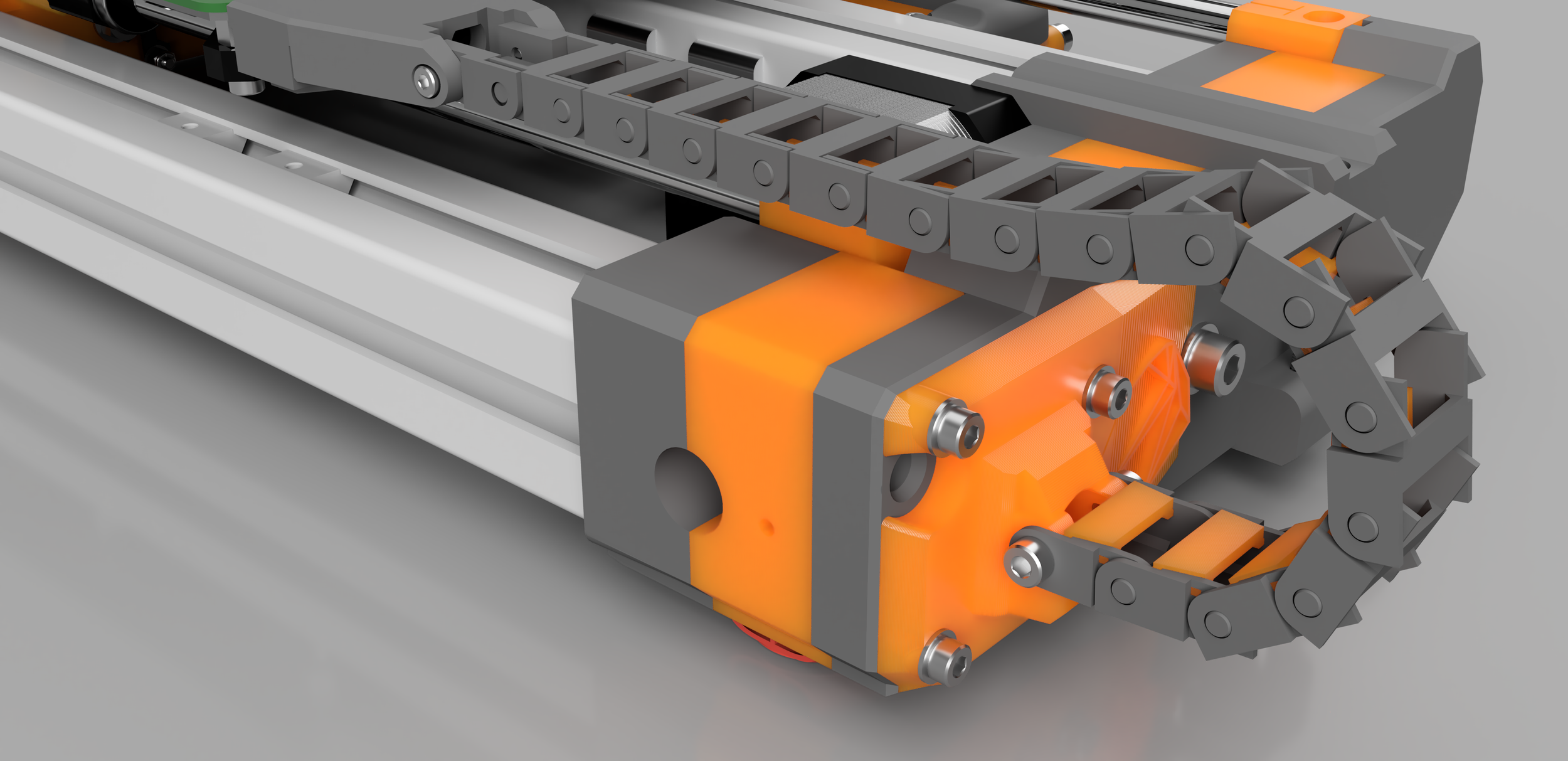

The print head borrows some elements from the Prusa MK3 head and the E3D Revo Hot End adapter for the Mini+ but rotates the Mini's cooling fan to allow for the third rod of the Super Mini's x-axis gantry. The additional weight of adding the third, carbon-fiber rod is made up by using hollow core rods for the first two.

The build makes extensive use of carbon-fiber infused Polycarbonate (the dark gray material) along with the Prusa-standard PETG (orange). Using PC/CF for the print head and the far end of the x-axis gantry further reduces the weight of the x-axis to ensure fast retractions even with the three-rod gantry.

Finally, the Prusa extruder design is replaced with an E3D Hemera with Bowden adapter.

super-v6 head

frankenhead